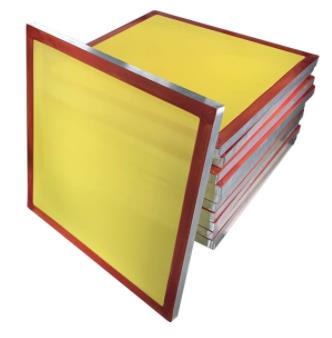

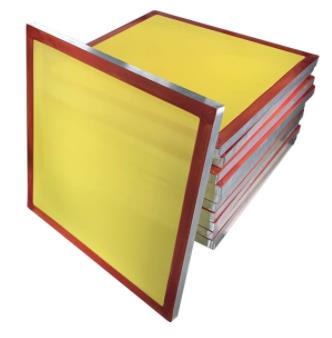

The screens often used in screen printing have two colors, yellow and white. Here we focus on the different characteristics of the two colors:

Screen printing needs to use photosensitive glue in the plate making process, and form the required pattern after exposure. During the exposure process, the screen uses ultraviolet light to cure the emulsion. Generally, the white Mesh will reflect or diffusely reflect the ultraviolet rays to the edge of the emulsion, and the edge should not be cured, resulting in a reduction in the resolution and clarity of the graphics, and sometimes the clear graphics cannot be completely formed.

But for the yellow Mesh, the Mesh only reflects yellow light and has no effect on light sensitivity and ultraviolet rays. It can produce clear images and fine lines, and improve the high precision of the film plate. Of course, the yellow wire Mesh takes more time in the exposure processing time than the white wire Mesh.

Here, huajin can provide white and yellow screen printing nets according to customer requirements. For more information, please contact us directly.